Water Soluble Circuit Boards: A Game-Changer for E-Waste

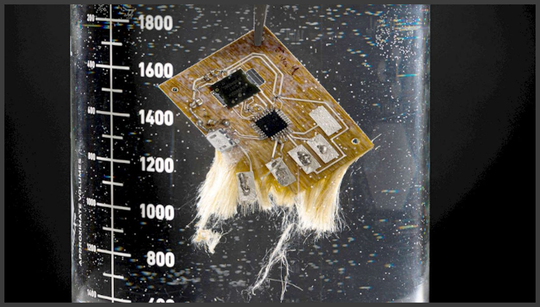

Water soluble circuit boards could be the future for e-waste, as a British start-up working with Infineon Technologies AG develops a plant-based PCB design that dissolves in water. The breakthrough could see Soluboard adopted by big tech companies worldwide, helping to drive an eco-conscious future.

With huge amounts of electronic parts being thrown away each year, and the potential for a 60% reduction in carbon emissions, the world’s first water-based recycling processes could prove to be a game-changer for the future of circuit boards. The design, which sees plant-based materials replace traditional glass fibre boards, aligns with the circular economy, and is in line with the WEEE Directive for e-waste management.

The world’s first fully recyclable commercialised PCB substrate is called Soluboard, and was co-developed by British start-up Jiva Materials and Infineon Technologies AG. Water-based recycling processes will lead to greater efficiencies in recovering valuable metals. Soluboard also dissolves in hot water, meaning that any leftover components can easily be reused.

Speaking about the potential for Soluboard, Jiva Materials CEO Justin Woolley says, “It took us three years to make Soluboard a reality, but we believe it is the start of a complete change in materials for circuit boards. So much of our planet is covered in forests, and this has inspired us to develop Jiva’s products from sustainable biomaterials. Soluboard shows that our vision is starting to become a reality, and we hope to continue developing technology that will benefit the environment.”

With a lower carbon footprint than traditional glass fibre boards, Soluboard could save 10.5kg of carbon and 620g of plastic per square meter of PCB. The potential for a 60% reduction in carbon emissions is promising, and based on current production figures, Soluboard could prevent around 77.4 tons of carbon emissions each year.

E-waste is a significant problem, with massive amounts of technology being wasted each year. Recycling electronic parts is an untapped source of rare Earth materials, and Soluboard offers a complete change in materials for circuit boards.

“Innovation is key to a circular economy and has a major role to play in preventing e-waste and preserving precious materials,” explains Dr. Tobias Bischof-Nahband, Head of Emerging Markets at Infineon Technologies AG. “The world’s first water-based PCB substrate is a milestone in the development of circular products and will hopefully serve as an example for other industries.”

For more information, please visit Soluboard.

}