Laying another brick on the superconducting wall

That’s how we’d describe the state of LK-99 Superconductor replication. As the frenzy around the seemingly magical material continues to grow, the scientists and DIY hobbyists attempting to lay their hands on some have found sourcing materials and replicating the manufacturing process to be particularly challenging. Now, an R&D engineer at Varda Space Industries – the company behind the LK-99 Space Pen – has been at the forefront of public replication efforts, sharing their work on Twitter and Twitch, and helping to demystify what’s proving to be a tricky process.

There’s no doubt that laying your hands on LK-99 is proving a challenge. The original Korean paper lacks any detailed information on the manufacturing process, meaning that multiple failed replication attempts have been made. Most notably, a team at Stanford University used the paper as a jumping-off point to develop their own LK-99 manufacturing process, but were unable to produce the material themselves.

In recent months, Andrew McCalip, an R&D engineer at Varda, has been at the forefront of public LK-99 replication efforts, open-sourcing his work on Twitter and Twitch. The original Korean paper, he explains, lacks the necessary detailed information on the manufacturing process, leading to many failed replication attempts.

“No one has been able to replicate the original paper,” he says. “The paper is pretty vague about what they did. They used a process that was very different from anything else that we’ve used.”

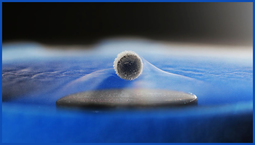

McCalip has been at the forefront of Varda’s replication attempts, and has made significant progress towards understanding the material and its properties. Most notably, the team has been able to create a small flake of LK-99, demonstrating the Meissner effect. The flake is now being sent to the University of Southern California (USC), where – if the tests are successful – it will be added to the textbooks as the first ever sample of LK-99.

Despite the obvious frustrations around replication, McCalip has remained upbeat and open in his public communications. His explanations around the LK-99 manufacturing process have been particularly helpful, as it’s the key missing element that’s been preventing replication efforts.

“Most people have failed at replicating LK-99,” McCalip explains. “They’ve failed because there’s no information in the paper about how to do it.”

The original Korean paper describes a complicated manufacturing process, which begins with the melting of red phosphorus with copper. However, the paper lacks details around key data for the baking process, including the temperature, baking time, and rate of quenching.

“The most important part is the quenching rate,” McCalip explains. “If you quench too fast, you get copper phosphide, if you quench too slow, you get red phosphorus.”

The addition of copper in the baking process also leads to unpredictable ratios of copper and lead atoms, which, according to McCalip, is the real secret behind the superconductive properties of LK-99. “This fact was not adequately specified by the authors of the paper,” he adds.

Following the creation of the LK-99 sample, the global supply chain has been strained by the frenzy around the material. Most notably, the price of copper phosphate, the base mineral used in the LK-99 manufacturing process, has skyrocketed to a whopping $20,000 (£15,000) per kilogram due to supply shortages.

While this may be a headache for LK-99 manufacturers, it presents no real problems for those looking to replicate the material. As McCalip notes, the base minerals required for LK-99 manufacturing are abundant, and the supply bottleneck may actually provide a silver lining for research efforts.

“Copper is more important [than phosphorus] but we can get copper,” he says. “The supply bottleneck is good, because it means that no one else can make a lot of LK-99.”

Despite the manufacturing hurdles and material supply issues, Varda’s replication efforts have been a success, and the team is now one step closer to understanding and replicating the magical properties of LK-99.

Unfortunately, this success may be of little comfort to other DIY replicators, as material supply issues may be forcing them to abandon their replication attempts. As we reported earlier this week, other LK-99 DIYers have been forced to admit defeat due to difficulties sourcing materials.

We’ve reached out to Andrew McCalip for comment on the LK-99 replication process, and will update this piece when we hear back.

Check out the Superconductor Flakes Discord for all the latest LK-99 breaking news.